- HOME

-

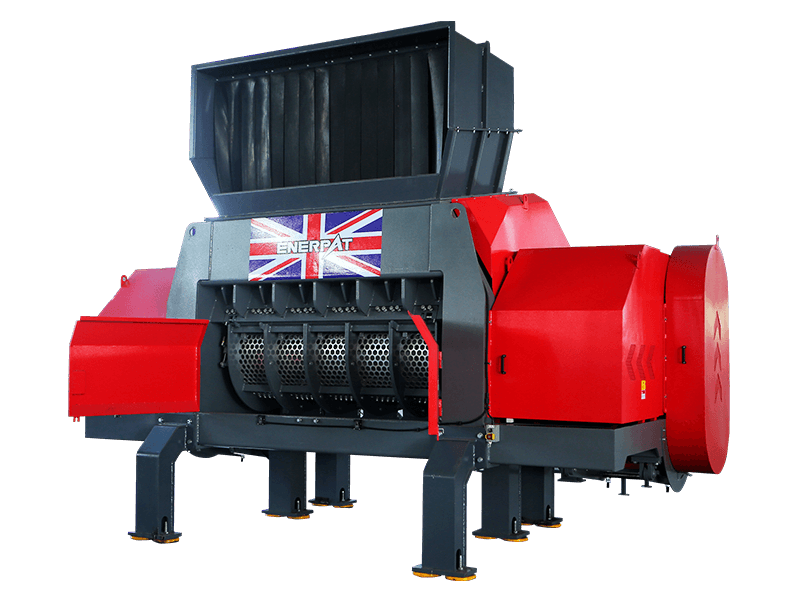

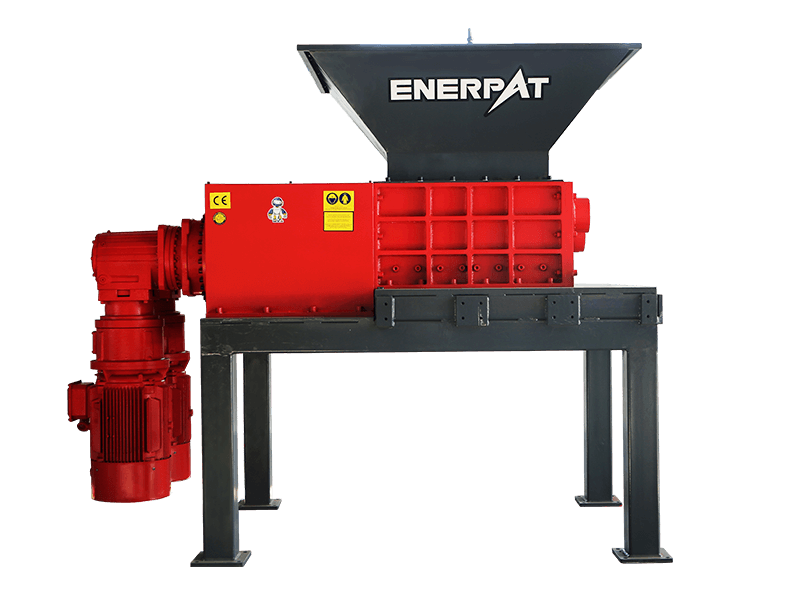

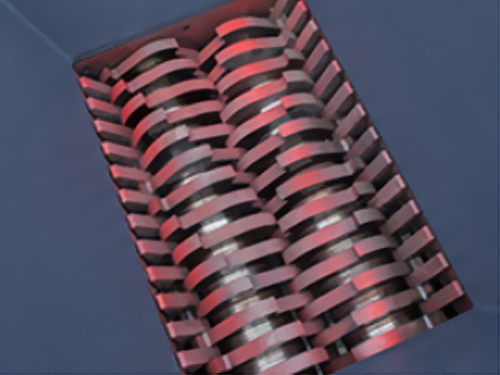

SHREDDERS

SHREDDERS

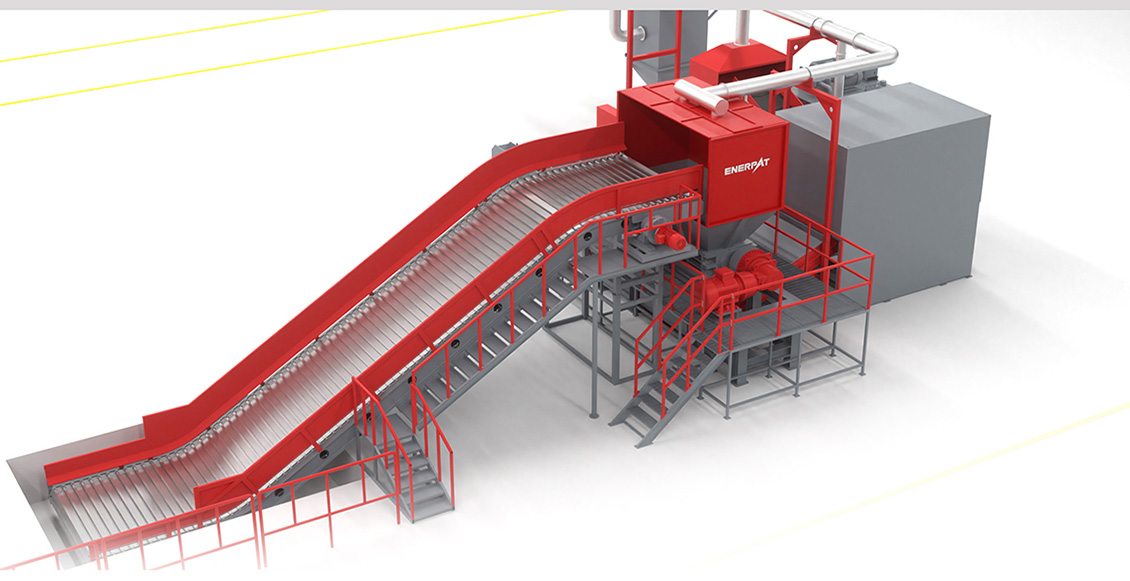

With a CE certificate and 8 patents, ENERPAT shredders are of high quality, durability, reliability, and efficiency. More importantly, all ENERPAT shredders are user-friendly to control and maintain.

-

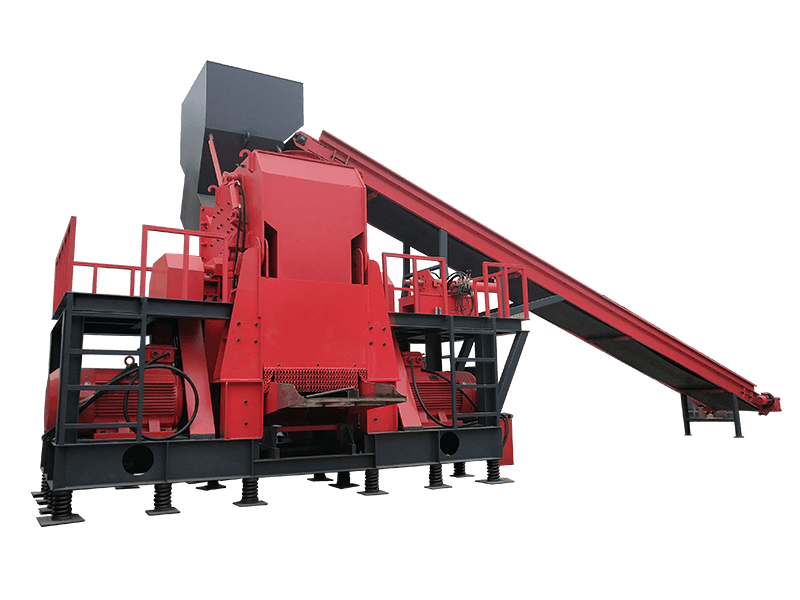

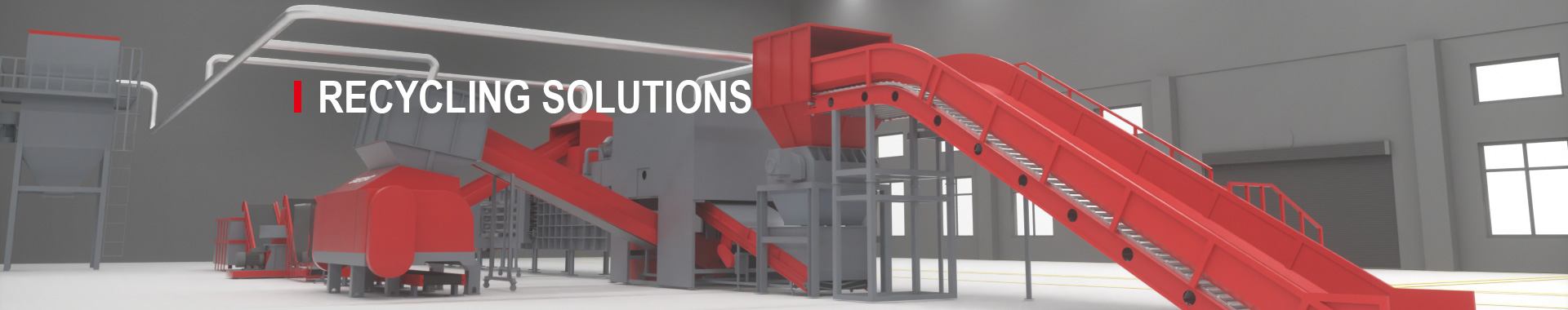

SOLUTIONS

SOLUTIONS

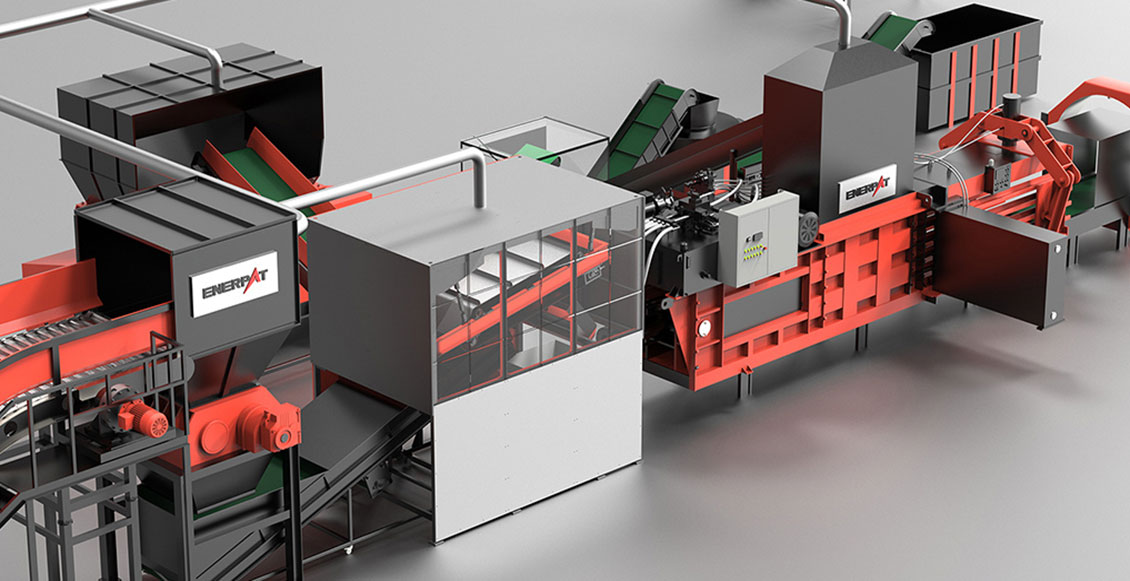

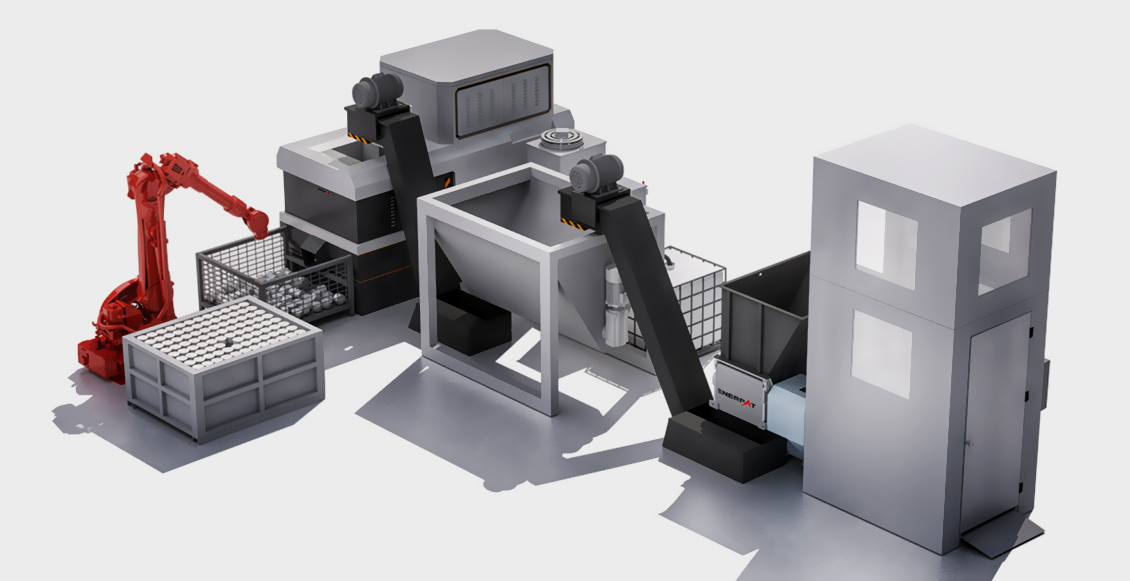

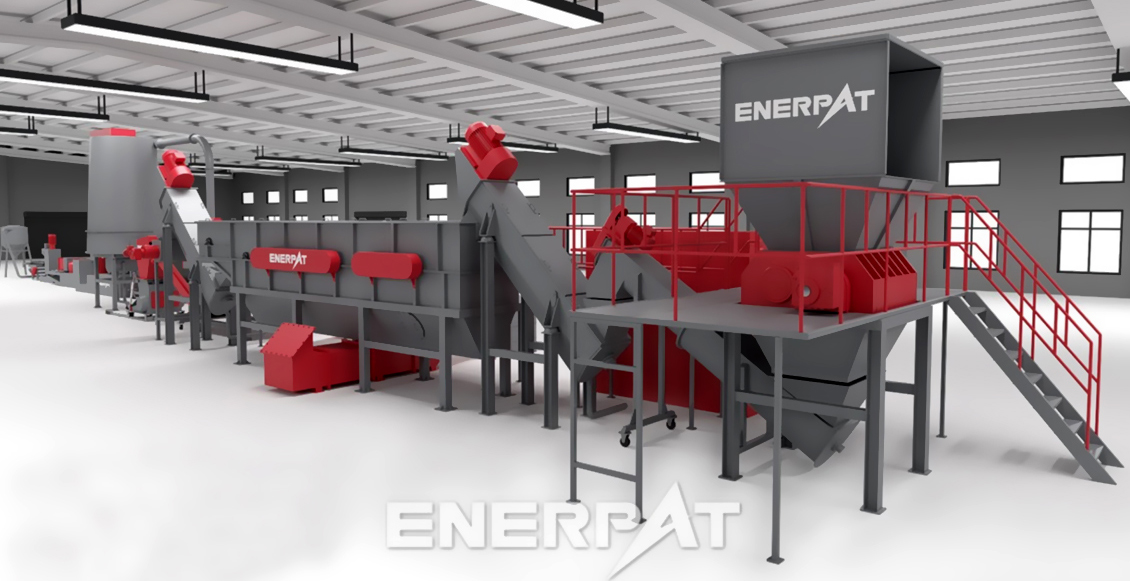

ENERPAT provides a full range of equipment to meet different needs of shredding and recycling, from which customers can select suitable machines for their purpose and convert their waste materials into profitable products.

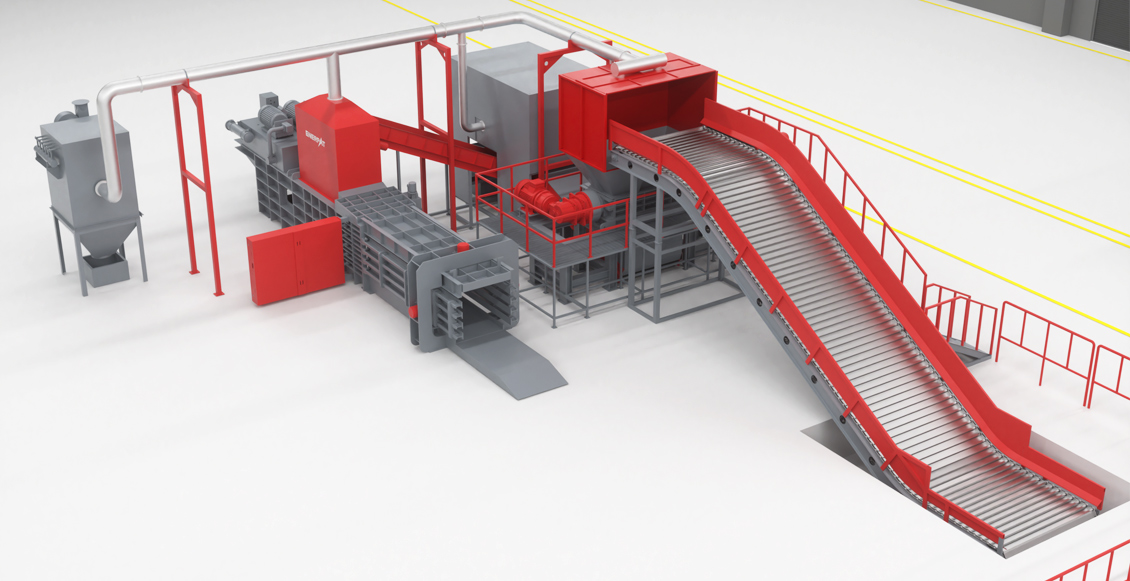

Oil Filters Recycling Line

Oil Filters Recycling Line

Pocket Coils Shredding and Sorting Solution

Pocket Coils Shredding and Sorting Solution

Disposal Solutions for Scrap Metal Chips

Disposal Solutions for Scrap Metal Chips

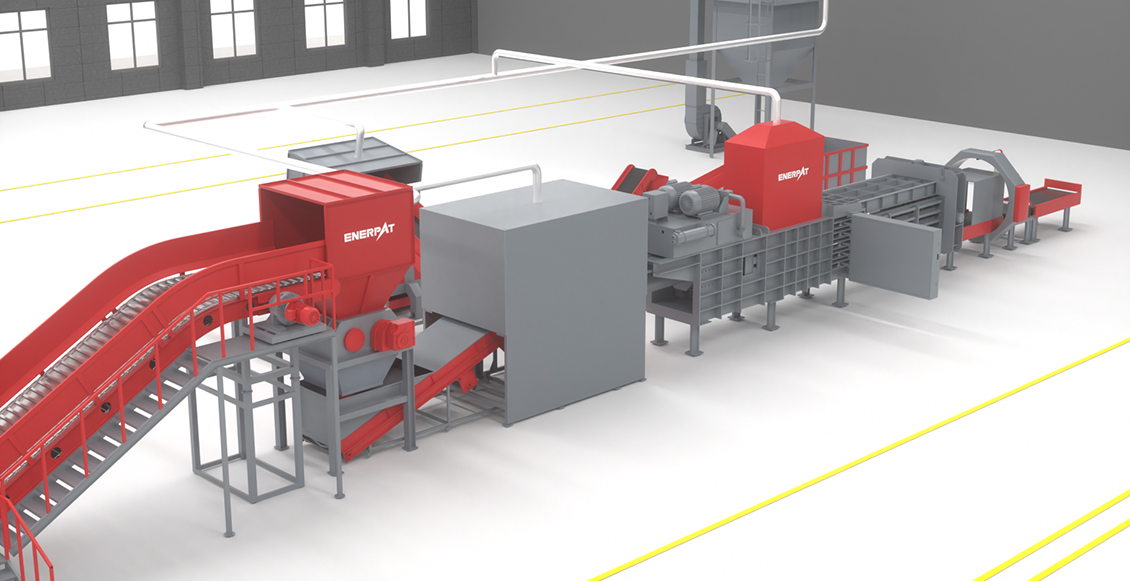

General Industrial Waste Recycling Solution

General Industrial Waste Recycling Solution

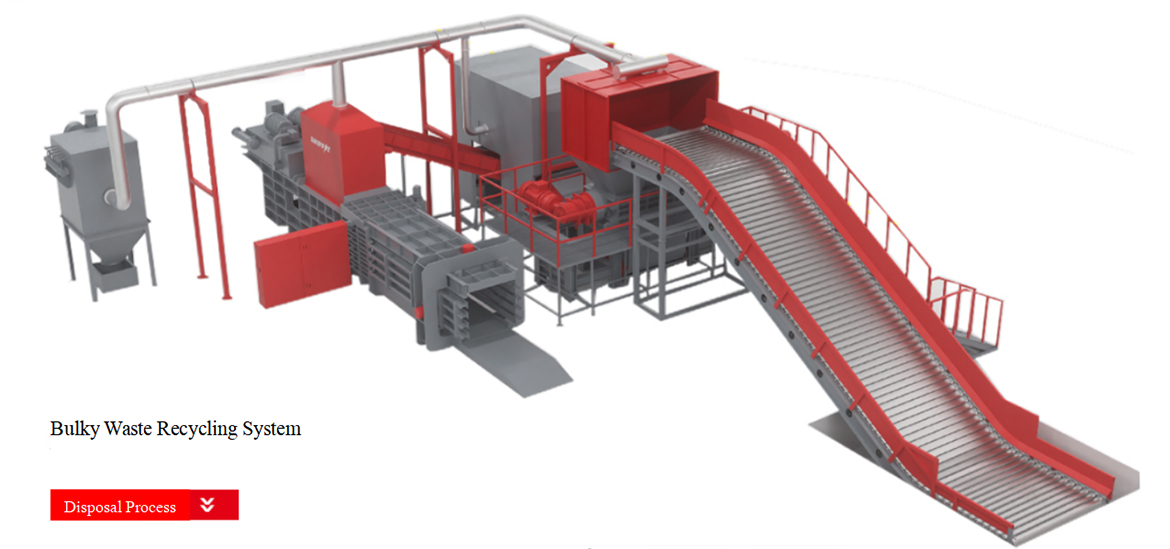

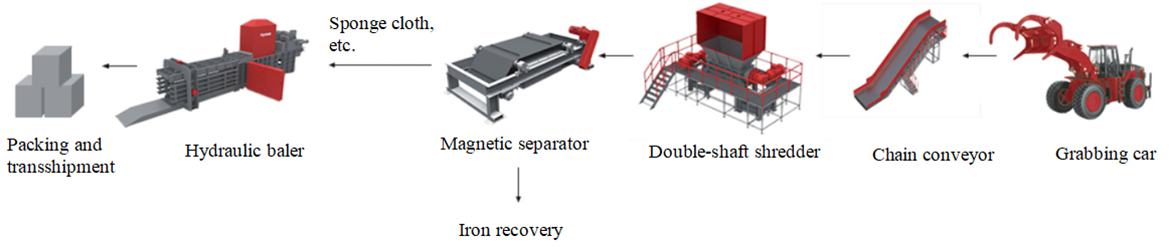

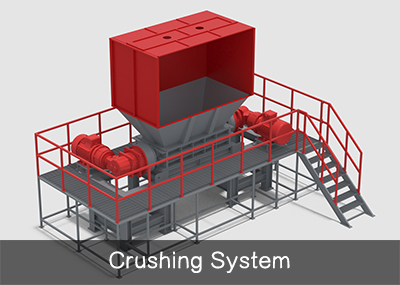

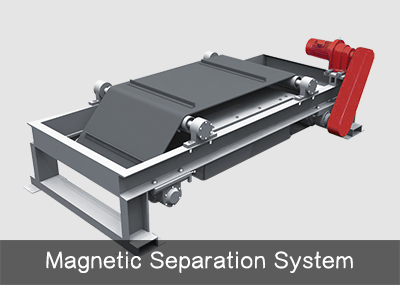

Bulky Waste Recycling System

Bulky Waste Recycling System

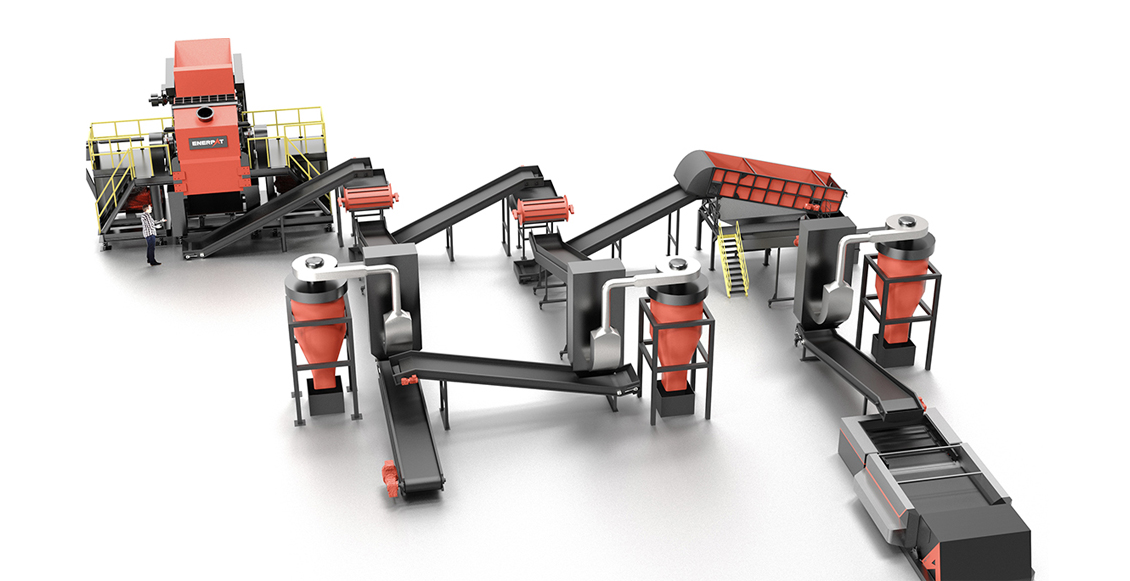

Home Appliances Shredding and Sorting Recycling Solution

Home Appliances Shredding and Sorting Recycling Solution

Plastic Film Washing and Pelletized Line

Plastic Film Washing and Pelletized Line

ACSR Recycling Solution

ACSR Recycling Solution

Cast Aluminum Shredding and Recycling Line

Cast Aluminum Shredding and Recycling Line

Lithium Ion Battery Recycling Plant

Lithium Ion Battery Recycling Plant

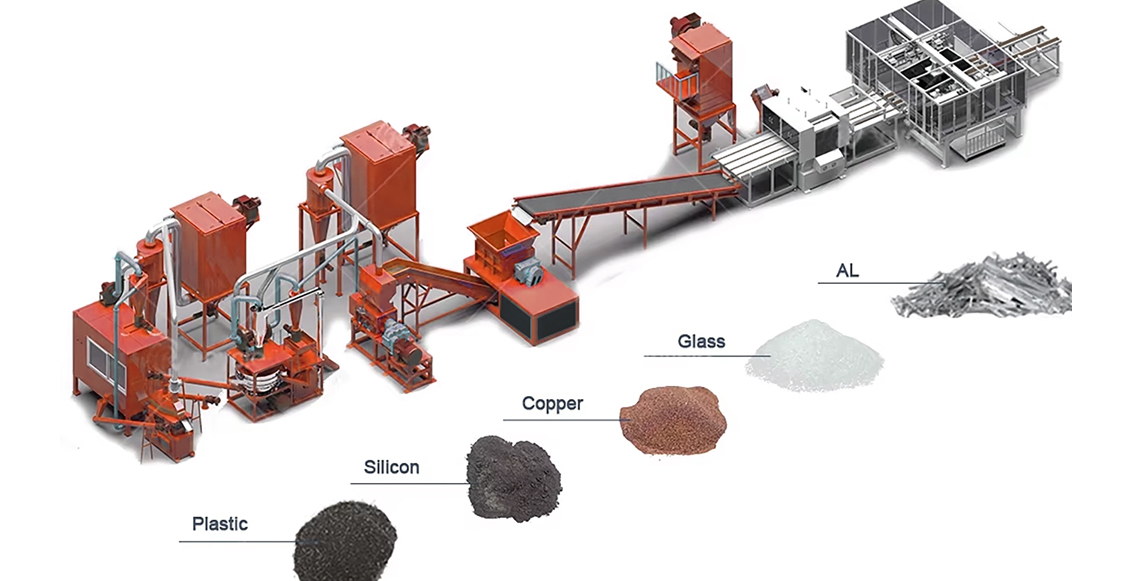

Solar Panel Recycling Equipment Line

Solar Panel Recycling Equipment Line

Aluminium Scrap Recycling Plant

Aluminium Scrap Recycling Plant

-

APPLICATIONS

APPLICATIONS

ENERPAT manufactures recycling machines that create more possibilities for different waste materials, such as wood, plastic, textile, metal, electronic waste, scrap cardboard, scrap furniture, tire, medical waste, municipal solid waste, industrial solid waste, construction & demolition waste etc.

-

PROJECTS

PROJECTS

ENERPAT has established cooperation with a great number of customers across the world, including many large and well-known enterprises.

-

SALES AGENT

SALES AGENT

If you are competent and interested in joining us as a sales agent, we are ready to answer any questions you may have at any time. Just contact us at your convenience.

-

NEWS

NEWS

Want to know more about ENERPAT in exhibitions by yourself? Please check the trade show information here and welcome to visit us!

-

ABOUT US

ABOUT US

ENERPAT has been specializing in waste shredding and recycling for over 80 years to maximize the value for customers of various waste materials by turning them into wealth in the most favorable way.

- CONTACT US

Single Shaft Shredder

Single Shaft Shredder Two Shafts Shredder

Two Shafts Shredder Four Shafts Shredder

Four Shafts Shredder Granulator

Granulator Hammer Mill

Hammer Mill Hydraulic Shredder

Hydraulic Shredder

Email:

Email:  Phone(Whats App):

Phone(Whats App): Add:

Add:

Whatsapp

Whatsapp

We want to say a great machinery from ENERPAT for America , every machine that we sell from ENERPAT is great. The quality of the machine is warranty.”